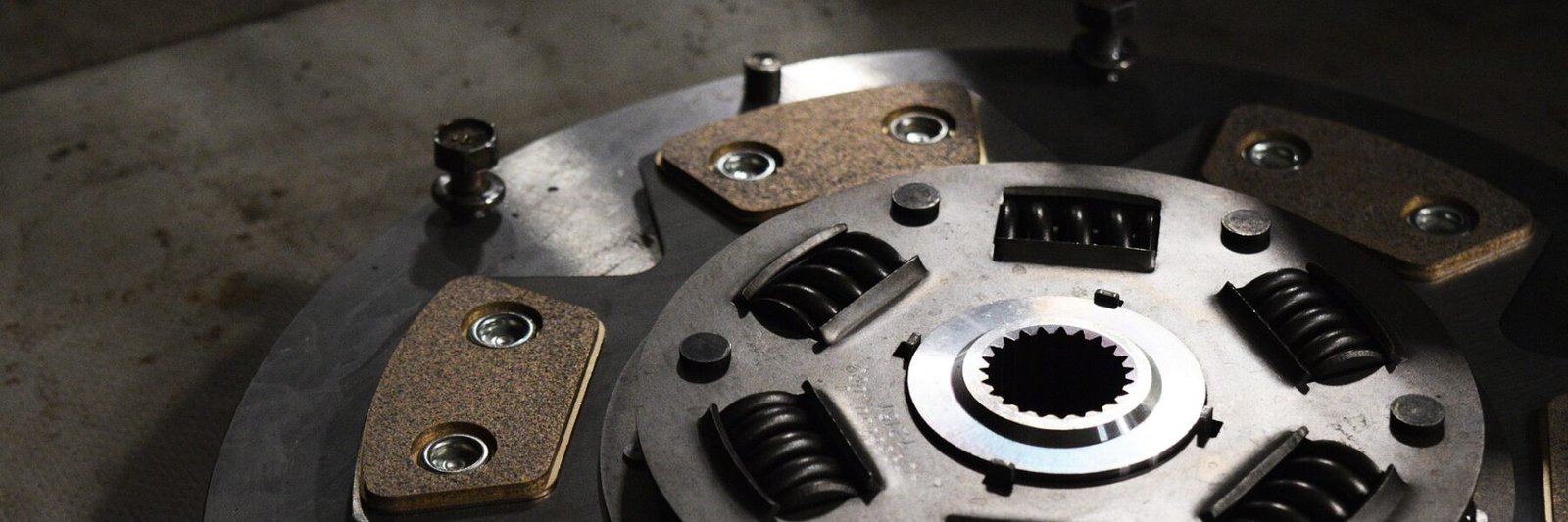

The slip clutch is a vital part of many industrial machines. There are three main styles of slip clutches, each performing a slightly different function depending on the machinery’s operation. These units, comprised of friction plates, springs, and pressure plates, regulate the torque between functioning components. Through the process of creating friction, these devices create energy that powers all kinds of machinery. By quickly Exploring the Role of Slip Clutches in Machinery, people can discover which type best meets their needs.

A Key Component When Machinery Needs to Run Smoothly

A slip clutch plays a vital role in machinery like conveyors, automatic doors, robotic systems used in assembly and packaging, and even large farming equipment. Each clutch design produces a different amount of torque, which is controlled by the compression of the internal springs. If the torque exceeds a set limit, the clutch will slip, releasing energy rather than abruptly stopping. This process prevents severe damage to the mechanical system.

Keeping Everything Moving in One Direction

One-way clutches exist in devices that necessitate drive in one direction rotation, transmitting torque from the input to the output shaft. Concurrently, the clutch can freely move or lock into place in the opposite direction. This is used when torque needs to apply to a particular direction when slippage should not occur to divert its path. If the clutch does fail, the components wedge together, causing friction production to halt. These are most commonly used to prevent mechanisms from reversing when the action could result in product and personnel harm.

Exact Control Requires the Accurate Limitation

Mechanical friction torque limiting slip clutches are necessary when torque control must be precise. They work by disengaging the clutch when it reaches a predetermined threshold for the applied torque. Friction between contact surfaces on the torque limiter transmits the power necessary to run machinery. Once this power reaches the threshold, the slip clutch halts transmission before an overload occurs. The device protects the equipment from unwanted damage and creates a safe work environment for the individuals working with and around the equipment.

Interlocking Parts Eliminate the Risk of Slippage

Finally, toothed jaw clutches offer non-slip capabilities in high torque transmission. The jaw teeth create a positive coupling between two devices, prohibiting slippage in any direction. Of course, this act limits the torque produced through the engagement speed, but it ensures a much higher level than a friction clutch. There are many different styles containing varying numbers of teeth, each design serving the specific need of the machine it operates inside. The tooth design also dictates torque capacity, allowing users to select the exact level they require.

Ensuring That Safety Standards Are Met for Years on End

Slip clutches provide a necessary safety in an industrial setting. When properly maintained, the clutch mechanisms can have a shockingly long life, but the presence of excess heat from high wattages can shorten their cycle. In most instances, the slip clutch will outlast the machinery it has been installed into and can be reused as spare parts when needed.