The integrity of pipelines and vessels is paramount in both production and the petrochemical industry. Even the most minor leaks can bring about considerable losses, whether from valuable sources or compromising safety in the worst-case state of affairs. Traditional leak detection strategies are frequently restricted in their effectiveness, mainly when dealing with minor or hidden leaks. However, ultrasonic digital camera leak detection generation has revolutionized monitoring and upkeep techniques in those industries.

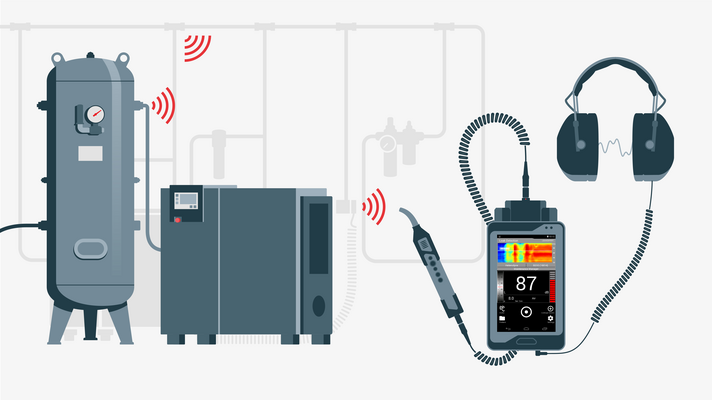

Ultrasonic digital camera leak detection offers a non-invasive and enormously correct method of identifying leaks in diverse commercial settings. Using ultrasonic sensors, these cameras can come across the excessive-frequency sound waves generated by leaks, even when they are too small to be visually apparent or in hard-to-reach locations. This functionality offers producers and petrochemical companies several massive benefits, ranging from more suitable safety and environmental protection to improved operational performance and value financial savings.

Here, we can explore how ultrasonic digital camera leak detection particularly blessings each manufacturing and petrochemical sector.

Manufacturing Industry

Here are ways wherein ultrasonic digicam leak detection is applied in manufacturing;

Quality Assurance: In production, ensuring the product is first-class is paramount. Ultrasonic digital camera leak detection aids in this component by identifying leaks or flaws in additives, including welds, seals, or joints, that could compromise the integrity of the last product.

By rapidly detecting these troubles, manufacturers can take corrective moves to save faulty products from entering the marketplace. Thus safeguarding their emblem’s popularity and minimizing pricey members.

Process Optimization: Leaks in commercial methods can result in inefficiencies, wastage of resources, and increased working expenses. Ultrasonic cameras allow producers to pinpoint the precise location of leaks, bearing in mind the upkeep or modifications to be made. By addressing leaks directly, producers can optimize their techniques, limit material wastage, and enhance average productivity.

Environmental Compliance: Many manufacturing processes contain the usage of dangerous substances or gases. Leaks in containment structures can release those substances into the surroundings, posing environmental hazards and regulatory compliance issues. Ultrasonic camera leak detection presents a non-invasive method for detecting leaks early, permitting producers to mitigate environmental risks and ensure compliance with emissions and pollutant management policies.

Equipment Maintenance: Industrial gadgets, which include pumps, valves, and garage tanks, are liable to wear and tear over time, which can result in leaks if not properly maintained. Ultrasonic digital camera leak detection helps proactive upkeep by enabling technicians to pick out ability leakage points earlier than they boost into principal issues. By enforcing an aggressive maintenance method, producers can minimize downtime, expand the lifespan of their devices, and decrease the chance of pricey upkeep.

Safety Enhancement: Leaks in business environments can pose extensive safety risks to people, mainly if they contain risky materials or gases. Ultrasonic camera leak detection identifies capacity safety risks by detecting leaks early and considering well-timed interventions. By retaining a safe operating environment, producers can defend the well-being of their personnel and save from accidents or injuries.

Energy Conservation: Leaks in compressed air structures, steam traps, or other electricity-in-depth techniques can result in significant electricity losses. Ultrasonic camera leak detection aids in identifying and addressing these leaks, thereby promoting power conservation and decreasing operational costs. Manufacturers can decorate their sustainability efforts by optimizing electricity usage while improving their backside line.

Petrochemical Industry

Here is how ultrasonic digital camera leak detection is utilized inside the petrochemical enterprise:

Early Detection of Leaks: One of the number one advantages of ultrasonic camera leak detection is its potential to discover leaks early. Early detection is vital in the petrochemical enterprise, where even a tiny leak can result in significant protection dangers and environmental harm. Using ultrasonic cameras, operators can quickly pinpoint the precise place of leaks, allowing spark-off intervention and restoring earlier than they boost into extra extensive incidents.

Non-Invasive Inspection: Ultrasonic camera leak detection gives a non-invasive method for examining system and piping structures. Unlike traditional methods that require shutdowns or physical dismantling of components for inspection, ultrasonic cameras may be used to test extensive areas without disrupting operations. This non-invasive method minimizes downtime and reduces the threat of injuries related to manual inspections, making it mainly correctly applicable to the petrochemical industry where operational continuity is paramount.

Real-Time Visualization: The other critical advantage of ultrasonic camera leak detection is its ability to provide actual-time visualization of leak sources. Advanced imaging software programs methods the records captured using ultrasonic sensors, producing visual representations of potential leak points on display. This real-time visualization lets operators quickly investigate the severity of leaks and prioritize response actions. By visually identifying leak resources, operators can expedite restoration efforts and prevent the escalation of the scenario.

Quantification of Leak Rates: In addition to detecting leaks, ultrasonic digicam generation can quantify leak fees, offering treasured information for danger evaluation and selection-making. By analyzing the depth of ultrasonic indicators emitted by leaks, operators can estimate the volume of fluid or gasoline escaping from a leak factor. These quantitative statistics allow operators to prioritize maintenance sports based totally on the severity of leaks and allocate assets more efficiently to mitigate dangers.

Enhanced Safety: By enabling early detection and visualization of leaks, ultrasonic camera technology contributes to improved protection within the petrochemical enterprise. By identifying leaks before they pose a significant danger to personnel or the environment, operators can implement timely interventions to mitigate risks and save accidents. Additionally, the non-invasive nature of ultrasonic digicam inspections reduces the publicity of employees to risky environments, similarly improving protection in petrochemical facilities.

Compliance with Regulations: The petrochemical industry needs to improve with stringent policies governing environmental safety and protection. Ultrasonic digicam leak detection allows petrochemical organizations to comply with these guidelines by permitting proactive leak detection and restoration practices. By demonstrating a dedication to environmental stewardship and protection, companies can avoid regulatory consequences and reputational damage associated with leaks and spills.

Cost Savings: Ultrasonic digicam leak detection can bring about substantial financial savings for petrochemical businesses. By identifying and repairing leaks early, corporations can decrease the lack of valuable sources, which include petroleum products or gases. Additionally, proactive renovation practices enabled using ultrasonic digicam generation help save you luxurious gadget failures and unplanned downtime. Over time, the cost of financial savings related to leak prevention and protection optimization can translate into great economic blessings for petrochemical agencies.