Embedded systems profoundly impact the product lifecycle, particularly in post-silicon support, within technology’s ever-evolving landscape. As a crucial phase of the product development cycle, post-silicon validation guarantees thorough testing for functional correctness of the manufactured embedded system design (chip) in an actual working environment. This article investigates how pivotal a role embedded systems play: they enhance efficiency and effectiveness in post-silicon support – ultimately directing the trajectory of overall product development.

Evolution of Post-Silicon Validation:

Over the years, the dynamic landscape of technology has substantially evolved in post-silicon validation. This crucial phase of product development traditionally focuses on scrutinizing the design’s functional correctness within a laboratory’s controlled and simulated environment. Yet, with embedded systems’ introduction initiating a transformative paradigm shift – it fundamentally redefines traditional boundaries for post-silicon validation processes.

Dedicated hardware and software components seamlessly integrate into larger systems or products, characterizing embedded systems. They are instrumental in redefining the approach to post-silicon validation, empowering processes beyond a controlled environment, unlike previous methodologies that primarily revolved around laboratory setups. This paradigm shift significantly steers focus towards real-world testing which replicates intended operating conditions for silicon, chips or system-on-chip (SOC).

Post-silicon validation’s primary objective steadfastly remains: it seeks to guarantee the functional correctness and qualification of a manufactured design for deployment. However, the methodology has undergone an evolution; specifically, with the inclusion of embedded systems –– this infusion opens doors for more holistic as well as realistic validation approaches. Simulating the real working environment: this is a strategy engineers employ to identify and rectify potential issues that might only appear in actual scenarios. In offering a more comprehensive–and hence, accurate–assessment of a product’s readiness for deployment, they ensure its optimal performance on field tests; indeed, this approach confirms whether it truly meets expected specifications prior to full-scale operation.

Embedded Systems Integration:

Post-silicon support landscape crucially incorporates embedded systems, which stand out for their integration into larger systems or products. Often, dedicated hardware and software components form these systems that enable a thorough validation approach: engineers embed testing mechanisms directly into the design to conduct real-time assessments of the product’s functionality in diverse scenarios–a process made possible by their comprehensive nature. Not only does this integration expedite the validation process, but it also elevates the product’s overall reliability.

Real-World Simulation:

By simulating real-world conditions with their remarkable capability, embedded systems create a crucial bridge between theoretical design and practical deployment in the post-silicon support realm: they play an integral role. Unlike traditional lab setups – which offer constrained environments – these systems empower engineers; dynamic simulations are possible that mirror closely—almost like twin images—the intricate operational circumstances expected for the final product out in the field.

This capability’s significance resides in its provision of a nuanced understanding of the development and validation process. Engineers, by emulating real-world scenarios, glean precious insights into product behaviour under diverse conditions such as temperature variations or electromagnetic interference. Anticipating potential issues that might arise during actual deployment is paramount at this simulation level; it guarantees not only functional correctness but also robustness and resilience against challenges from the real world in delivered end-products.

Simulating real-world conditions introduces a paradigm shift in post-silicon support; it overcomes the constraints of traditional lab testing. Such conventional methods frequently struggle to capture the complexity and variability present within operational environments in which products are expected to function. Engineers can use embedded systems as virtual testbeds: this allows them to expose designs to an array of conditions—unpredictable like their actual usage scenarios.

Rapid Prototyping and Iterative Development:

During the post-silicon support phase, embedded systems play a crucial role in enabling rapid prototyping and iterative development. Engineers leverage this technology to swiftly execute alterations, updates or optimizations within the embedded software; thus creating a dynamic environment for testing and validation. This approach speeds up both issue identification and resolution significantly – ultimately reducing time-to-market while augmenting overall agility throughout the product development process.

Remote Monitoring and Diagnostics:

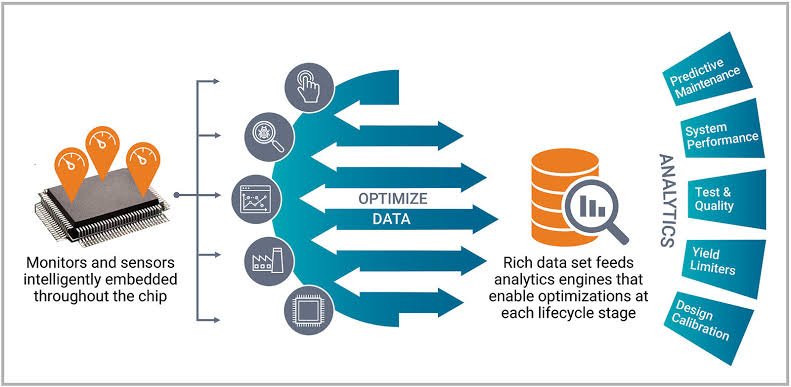

Enabling remote monitoring and diagnostics, the integration of embedded systems streamlines the post-silicon support process. This capability empowers engineers to actively monitor a product’s deployed performance in real-time, receive feedback and diagnose issues from a distance. Consequently, through this proactive approach towards maintenance and support aspects of the lifecycle; downtime minimization is achieved while ensuring an uninterrupted user experience: a testament – indeed–to advanced technology at its finest.

Improved Fault Tolerance and Reliability:

During post-silicon support, products’ fault tolerance and reliability significantly benefit from the incorporation of designing embedded system. These sophisticated mechanisms—equipped with advanced error detection and correction capabilities—not only autonomously identify potential failures but also proactively address them. Such a robust, proactive approach dramatically minimizes the risk of system failures or malfunctions in real-world scenarios to enhance overall product performance.

Optimizing Power Consumption:

Embedded systems function critically in power consumption optimization during post-silicon support in the energy efficiency era. Engineers can fine-tune a product’s energy usage by directly embedding intelligent power management features into its hardware and software, which not only contributes to environmental sustainability but also extends battery-powered device lifespan – an essential factor for many contemporary products’ success.

Challenges and Considerations:

Embedded systems, while offering several advantages for post-silicon support, present their own set of challenges: the intricate integration of hardware and software components demands meticulous consideration; potential unforeseen interactions require immediate attention. Moreover–engaging with a diverse range of environments and use cases to ensure compatibility–proves an ongoing navigational challenge that engineers must surmount.

Future Outlook:

Embedded systems’ evolution persistently molds the post-silicon support landscape. Further innovations in embedded systems, enhancing product development’s efficiency, reliability and adaptability are expected with advancing technology. Poised to play increasingly significant roles in these developments are artificial intelligence, machine learning and advanced analytics; they offer predictive capabilities while refining the process of post-silicon validation further.

Conclusion:

Undeniably, semiconductor design company have profoundly influenced the impact of post-silicon support in the product lifecycle. Not only have these systems revolutionized validation processes through their integration but they’ve also paved the way for more robust, reliable and adaptive products. Looking ahead to future prospects; a symbiotic relationship between embedded systems and post-silicon support appears promisingly–even crucially–integral in driving continuous innovation and advancement: it will ultimately shape our technological landscape for years to come.