3d printing is among the most transforming technologies of today’s digital era, and it’s on the verge of bringing a paradigm shift. This advancement is exciting in itself as it lets anyone turn their idea into a reality.

Facts About 3d Printing That You Should Not Miss

You may be using this technology in your daily life, but there are some interesting facts about it that you may not know. On this note, let’s dive into compelling facts about additive manufacturing that you should not miss.

It’s older than you imagine

When we think of modern technologies, 3d printing comes to our minds, but it’s not today’s innovation. 3d printing got popular in the 2000s when manufacturers started using the FDM method and nylon as a filament. However, 3d printing first appeared in the 1980s; Chuck Hull first came with the stereolithography process. In this process, he used UV lasers to solidify photopolymer in a layered fashion.

3d printing is not a one technology

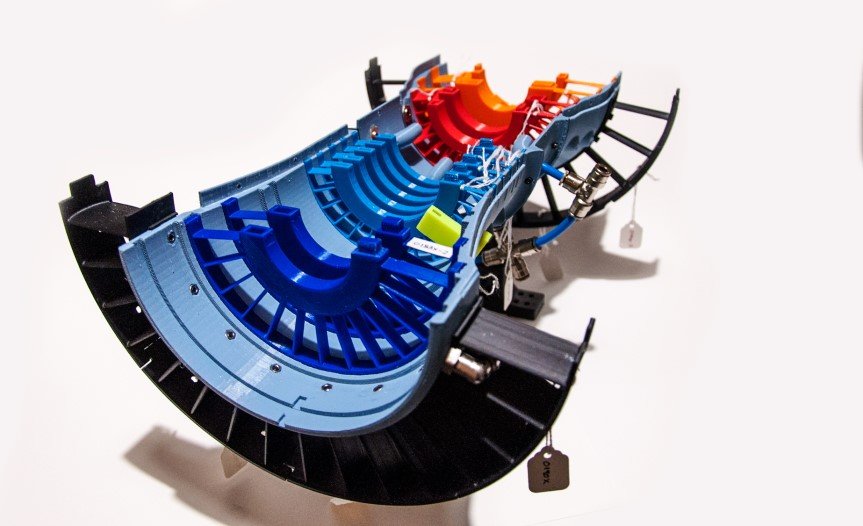

3d printing is not a single technology as it has multiple sub-methods that cater to different printing requirements. Apart from the widely used FDM, there are several professional-grade printing technologies available with additive manufacturing. Some of the widely used 3d printing services are SLS (Selective Laser Sintering), DMLS (Direct Metal Laser Sintering), SLM (Selective Laser Melting), SLA, DLP.

Engineers use various methods to work with filaments, including titanium, stainless steel, biodegradable filaments, and more. Many industries, including automotive, aerospace, use DMLS and SLM methods for metal printing.

Beyond prototyping

Earlier, this technology was only limited to creating 3d printing prototypes, but more industries are now integrating it with their main product lineup. Additive manufacturing is a cost-effective technology in terms of many applications, and that’s why industries are using it. Be it creating customized vehicle parts or special-edition fashion accessories, 3d printing is gradually replacing traditional methods.

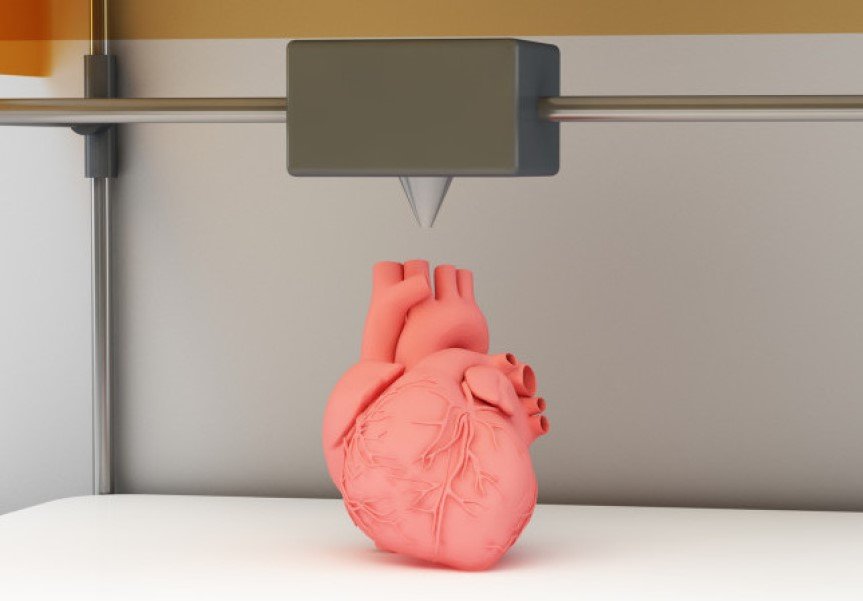

3d printing can save lives

Healthcare is among the primary industries, and it is leveraging 3d printing to its full potential. Engineers and doctors are using additive manufacturing to produce custom prosthetics that are more useful than traditional ones. Along with prosthetics, doctors are using 3d printing to print heart and kidney models to mimic complexities found in a patient’s body.

This practice allows doctors to understand the problem more comprehensively as compared to Xray and other reports. Recently, engineers produced thousands of PPE equipment during the COVID-19 outbreak.

3d printing is possible in space

Not only on earth, but astronauts are also using it to print custom parts during their space exploration. Carrying mechanical parts is risky, and they might break due to hyper pressure. To avoid this from happening, space agencies integrate 3d printers so that astronauts can print essential parts when they need them.

This innovation helps space agencies minimize the overall risk of the mission and is more cost-effective than carrying the parts.

It lowers down production cost

Cost optimization is a primary reason why several companies, regardless of their industries, are adopting this technology. When printing a limited batch of personalized prototypes or final products, the cost will be much higher using the traditional process.

On the other hand, 3d printing can operate a small batch at a reduced cost, and it also doesn’t require any additional supporting pre-production settings. Due to the growing demand, many startups are now offering 3D printing service in Perth, Melbourne, and many other areas.

You can build a house

Yes, it’s possible to build portable houses using this advancement which is a boon to serve people during any emergency. It is possible to print houses in parts and then they are easy to transport and assemble. It’s easy for engineers to build a small house in less than 2 days, far ahead of the traditional process.

This construction method is more cost-effective and faster, and it might get mainstream in the upcoming time. As of now, engineers are printing these houses for temporary living and storage purposes. Also, engineers can print more complex geometries that are not possible with traditional construction. Many companies are already offering this kind of 3d printing in Australia and other countries.

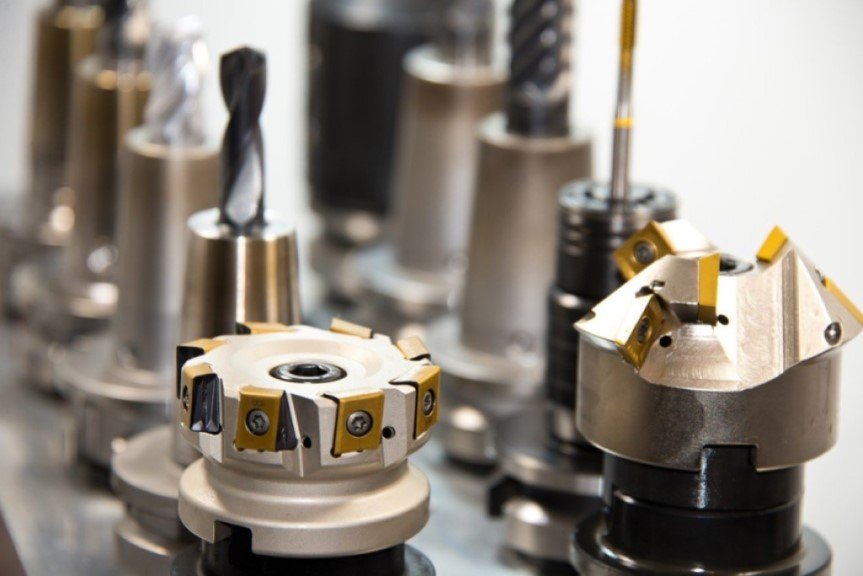

3d printing improves tooling

Tooling is a necessary manufacturing process, and 3d printing can streamline this job with its advanced applications. Engineers can create accurate tools and custom fixtures that are hard to design using the conventional process. 3d printing allows higher customization in the manufacturing of tools, and it’s helpful in various industries.

3d printed food

You can print food using a 3d printing machine, and people are already printing chocolates and vegan steaks with this technology. Advanced 3d printers can print synthetic tissues which gives a real-like texture to the food. This innovation will help to reduce greenhouse gas emission by producing synthetic meat. However, there is a long way to go to 3d food printing. Many innovative hubs are already offering this type of 3D printing in Perth, WA and other areas.

Conclusion | Interesting Facts About 3d Printing That You Should Not Miss

3d printing technology is here to stay with us, and it will bring a massive transformation across industries. Be it healthcare, automotive, aerospace, or education— additive manufacturing will improve manufacturing standards. If you also have any innovative idea in mind, it’s the right time to get started and get a 3d printing quote. Turn your imagination into an exciting idea with additive manufacturing.

[…] printers are popular among home users for good prices and printing quality. But many users face error state issues on Epson printers. Like other hardware devices, the Epson […]