Innovation has always been at the forefront of technological advancements, driving industries towards new horizons. One such innovation that is revolutionizing the manufacturing landscape is industrial laser cutting machines. These cutting-edge devices are transforming the way materials are processed, offering unparalleled precision, efficiency, and versatility. In this article, we will delve into the world of industrial laser cutting machines and explore how they are shaping the future of manufacturing.

1. The Evolution of Laser Cutting Technology:

Industrial laser cutting machines have come a long way since their inception, from the early CO2 laser cutters to the advanced fiber and diode lasers used today, the technology has witnessed significant advancements. The precision and speed of these machines have improved, making them indispensable tools for various industries, including automotive, aerospace, electronics, and more.

2. Unmatched Precision and Versatility:

One of the key benefits of industrial laser cutting machines is their ability to deliver unmatched precision. These machines can cut through a wide range of materials, including metals, plastics, wood, and even fabrics, with exceptional accuracy. The laser beam can be precisely controlled, allowing for intricate designs, sharp corners, and complex geometries that were previously difficult to achieve.

3. Enhanced Efficiency and Productivity:

In the fast-paced world of manufacturing, efficiency is crucial. Industrial laser cutting machines offer unparalleled speed and efficiency compared to traditional cutting methods. With rapid cutting speeds and minimal downtime for tool changes, manufacturers can significantly reduce production time and increase overall productivity. Moreover, these machines can automate the cutting process, eliminating the need for manual labor and minimizing human error.

4. Material Maximization and Waste Reduction:

Traditional cutting methods often result in significant material wastage. However, industrial laser cutting machines optimize material utilization by minimizing kerf width (the width of material removed during cutting) and nesting parts efficiently. This not only reduces material waste, but also leads to cost savings and a more sustainable manufacturing process.

5. Flexibility and Adaptability:

Industrial laser cutting machines offer unparalleled flexibility and adaptability, allowing manufacturers to quickly adapt to changing demands and market trends. These machines can switch between different cutting patterns, accommodate various material thicknesses, and easily adjust cutting parameters. With such versatility, businesses can stay agile and meet the evolving needs of their customers.

6. Safety and Environmental Friendliness:

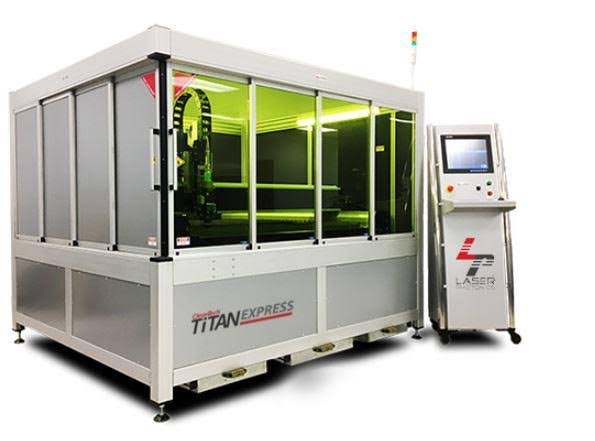

In addition to their precision and efficiency, industrial laser cutting machines also prioritize safety and environmental considerations. They often come equipped with safety features like protective enclosures, automated shutdown mechanisms, and exhaust systems to ensure the well-being of operators and minimize hazards. Furthermore, laser cutting produces minimal waste, reduces the need for harmful chemicals, and has a lower carbon footprint compared to traditional cutting methods.

7. Integration with Industry 4.0:

Industrial laser cutting machines are not isolated entities, but are an integral part of the Industry 4.0 revolution. These machines can be seamlessly integrated into digital manufacturing ecosystems, communicating with other machinery, sensors, and software systems. This integration enables real-time monitoring, data analysis, predictive maintenance, and optimization of the cutting process, further enhancing efficiency and productivity.

Conclusion

Industrial laser cutting machines have undoubtedly become the backbone of modern manufacturing. Their ability to deliver unmatched precision, efficiency, and versatility is transforming industries and shaping the future of manufacturing. As technology continues to evolve, we can expect further advancements in laser cutting technology, unlocking even more possibilities and pushing the boundaries of innovation in the manufacturing sector. With industrial laser cutting machines, the future of manufacturing is brighter than ever before.