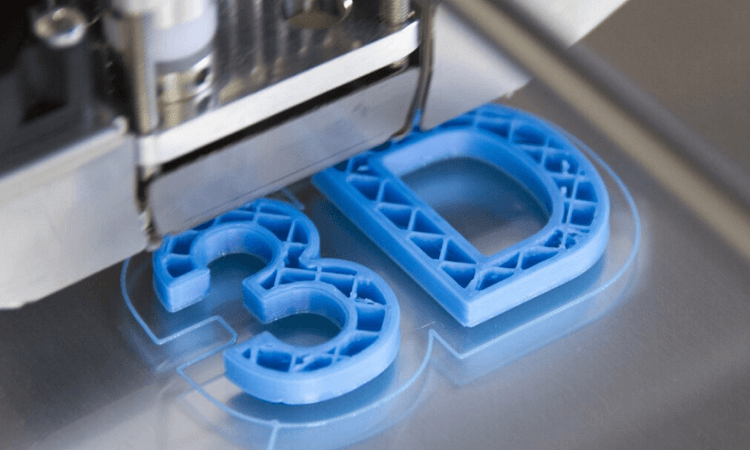

The demand for 3d printing services is surging rapidly as more industries are adopting these technological advancements in their regular operations & Top 10 Disruptive 3D Printing Challenges & Solutions. Whether automotive, healthcare, or construction, 3d printing technology is now becoming a fundamental part of the entire business execution.

Top 10 Disruptive 3D Printing Challenges & Solutions | Top 3D Printing Problems and Solutions

Even with so many complex implementations, we are still scratching the surface, and there are many underlying 3d modeling challenges that industries are aligned towards finding solutions.

3d printing in healthcare

This technology is proven to be a vital boon in the medical field because of its prosthetics development miracles. Be it reconstructing the jaw or replicating a human knee function, surgeons are adopting these facilitations with more confidence.

Challenge with 3d printed equipment

Many prominent industry players are leveraging this technology to ease their manufacturing processes. But, the operational costs are still higher as compared to the conventional production setup.

This challenge can be addressed by improving the availability of modeling materials. Higher available resources will help the companies to mass-produce the equipment sets and take this technology towards more usability.

3d printed prosthetics manufacturing

The prosthetics industry surged significantly with the involvement of this technology. As a set of medical equipment used for manufacturing is not widely available in many remote areas, the accessibility hurdle is there.

The top management can end this problem by not considering additive manufacturing as a ‘replicator’ but as a wholesome revolution for their institute.

Standardization of surgical tools

The solution towards solving the uniformity issue will lead to cost reduction and frequent usage of these surgical tools, following a specific set of production rules to provide quality 3d printing in Pune, Delhi, and other tech hubs.

Research & development of materials

To improve the customer experience and to deliver outstanding products, companies are facing the challenge of discovering materials that bring more efficiency to existing ones.

For example, 17-4 PH stainless steel is an approved material for the 3d print, which is less expensive. Still, companies need more affordable and sustainable materials to make this technology mainstream, like conventional ones.

Resourceful training

3d print in India is becoming an integral part of many industries. Still, the need for innovative training is a gap that needs to be filled by good institutes dedicatedly working towards this tech’s advancements.

However, many 3d printing service provider hubs are trying to tackle this challenge by conducting regular workshops for people who share a keen interest.

Customization efficiency

Running flawless customization over new material could be challenging, especially when the work is going around surgical procedure or equipment manufacturing. Machine hardware optimization is among the top demanding use cases when it comes to offering patient-specific solutions.

This customization optimization is possible when the experts will test the performances of various printing materials over a scale.

Proof of concepts

As of now, the proof of concepts regarding manufacturing new body prosthetics or complex projection of a damaged machinery part needs more refinement for broader acceptance.

To bridge this gap, especially when working on 3d print in the medical industry, companies need to have more data-driven proof of concepts that will boost the treatment of more critical issues.

Scope in recyclability

When these printed equipment are compared with traditionally made-parts, recyclability is more challenging in additive manufacturing due to the composition of the material.

To fix this issue, companies need to focus on various material R&D processes to devise more reusable materials for varied purposes.

Post Processing

Printed objects require higher post-processing efforts as compared to conventional products. This is because of the particular type of materials used in production.

For reducing the post-processing efforts, manufacturers need to work on producing more refined materials that can withstand mass-production and offer greater convenience.

Conclusion | Top 10 Disruptive 3D Printing Challenges & Solutions

These were the top ten 3D printing challenges that companies are tackling using better use cases and production methods. As we more evolve with this tech, the usability will grow naturally, and the production challenges will be significantly lower.